Klaipėda state College

TECHNICAL FACULTY

Transport engineering

DIESEL ENGNE HYSTORY

Work was carried out by : ATE 35-1 group student

Lecturer inspected the work :

Klaipėda, 2015

SUMMARY

The word technology refers to the making, modification, usage, and knowledge of tools, machines, techniques, crafts, systems, and methods of organization, in order to solve a problem, improve a preexisting solution to a problem, achieve a goal, handle an applied input/output relation or perform a specific function. It can also refer to the collection of such tools, including machinery, modifications, arrangements and procedures. Technologies significantly affect human as well as other animal species’ ability to control and adapt to their natural environments.

Rudolf Diesel and his invention diesel engine is the object of the paper. The goal of the paper is to analize this invention, talk about Rudolf Diesel and his theory of diesel engine, its advantages and disadvantages, types and working principles. The diesel engines of today are refined and improved versions of Rudolf Diesel’s original concept. They are often used in submarines, ships, locomotives, and large trucks and in electric generating plants.

Technology has affected society and its surroundings in a number of ways. In many societies, technology has helped develop more advancedeconomies (including today’s global economy) and has allowed the rise of a leisure class. Many technological processes produce unwanted by-products, known as pollution, and deplete natural resources, to the detriment of the Earth and its environment.

Contents

INTRODUCTION 4

1.Rudofl Diesel. Biography 5

2.HISTORY 6

3.How diesel engines work 7

3.1. Early fuel injection systems 7

3.2. Mechanical and electronic injection 8

3.3. Direct injection 8

4.Types 9

4.1. Size Groups. 9

4.2. Basic Types of Diesel Engines 9

4.3.Gas generator 10

4.4.Modern High- and Medium-speed Engines 10

5.Advantages and disadvantages versus spark-ignition engines 11

5.1.Power and fuel economy 11

5.2.Emissions 11

5.3.Noise 12

6. SAFETY 13

6.1. Fuel flammability 13

6.2. Maintenance hazards 13

Fuel injection introduces potential hazards in engine maintenance due to the high fuel pressures used. Residual pressure can remain in the fuel lines long after an injection-equipped engine has been shut down. This residual pressure must be relieved, and if it is done so by external bleed-off, the fuel must be safely contained. If a high-pressure diesel fuel injector is removed from its seat and operated in open air, there is a risk to the operator of injury by hypodermic jet-injection, even with only 100 psi pressure. The first known such injury occurred in 1937 during a diesel engine maintenance operation. 13

CONCLUSION 14

Key Vocabulary 15

17

References 17

INTRODUCTION

In this paper I‘m going to introduce the Diesel Engine. It is a review, in witch I am going to gather information about this invention and my topics will be in three parts: first is Rudolf Diesel biography, second how diesel engines work, its types and also advantages and disadvantages and safety ofcourse. This topic, which I have chosen, is really relevant, because the diesel engine became widespread in many other applications, however, such as stationary engines, submarines, ships, and much later, locomotives, trucks, and in modern automobiles.

Diesel technology is constantly being improved. Government pressure to produce low-emission diesel engines for passenger vehicles, trucks, buses, and farm and construction equipment has resulted not only in low-sulfur diesel fuels but also specialized catalytic converters, advanced filters, and other devices to cut down or destroy toxic emissions.

Rudofl Diesel. Biography

Diesel was born in Paris, France in 1858 the second of three children of Elise (born Strobel) and Theodor Diesel. His parents were Bavarian immigrants living in Paris. Theodor Diesel, a bookbinder by trade, left his home town of Augsburg, Bavaria, in 1848. He met his wife, a daughter of a Nuremberg merchant, in Paris in 1855 and became a leather goods manufacturer there.

Figure 1. Rudolf Diesel

Rudolf Diesel spent his early childhood in France, but as a result of the outbreak of the Franco-Prussian War in 1870, his family (as were many other Germans) was forced to leave. They settled in London. Before the war’s end in 1874, however, Diesel’s mother sent 12-year-old Rudolf to Augsburg to live with his aunt and uncle, Barbara and Christoph Barnickel, to become fluent in German and to visit the Königliche Kreis-Gewerbsschule (Royal County Trade School), where his uncle taught mathematics.

At age 14, Rudolf wrote a letter to his parents stating that he wanted to become an engineer. After finishing his basic education at the top of his class in 1873, he enrolled at the newly-founded Industrial School of Augsburg. Two years later, he received a merit scholarship from the Royal Bavarian Polytechnic of Munich, which he accepted against the wishes of his parents, who would rather have seen him start to work.

Diesel understood thermodynamics and the theoretical and practical constraints on fuel efficiency. He knew that as much as 90% of the energy available in the fuel is wasted in a steam engine. His work in engine design was driven by the goal of much higher efficiency ratios. After experimenting with a Carnot Cycle engine, he developed his own approach. Eventually, he obtained a patent for his design for a compression-ignition engine. In his engine, fuel was injected at the end of compression and the fuel was ignited by the high temperature resulting from compression. From 1893 to 1897, Heinrich von Buz, director of MAN AG in Augsburg, gave Rudolf Diesel the opportunity to test and develop his ideas. Rudolf Diesel obtained patents for his design in Germany and other countries, including the USA.

HISTORY

D

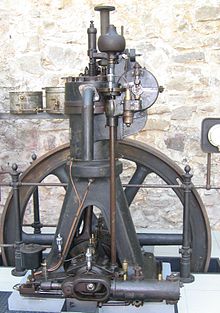

Figure 2. Diesel’s original 1897 engine on display at the Deutsches Museum in Munich, Germany

iesel designed many heat engines, including a solar-powered air engine. In 1892 he received patents in Germany, Switzerland, the United Kingdom and filed in the United States for “Method of and Apparatus for Converting Heat into Work”. In 1893 he described a “slow-combustion engine” that first compressed air thereby raising its temperature above the igniting-point of the fuel, then gradually introducing fuel while letting the mixture expand “against resistance sufficiently to prevent an essential increase of temperature and pressure”, then cutting off fuel and “expanding without transfer of heat”. In 1894 and 1895 he filed patents and addenda in various countries for his Diesel engine; the first patents were issued in Spain, France and Belgium in December 1894, and in Germany in 1895 and the United States in 1898. He operated his first successful engine in 1897.

Though best known for his invention of the pressure-ignited heat engine that bears his name, Rudolf Diesel was also a well-respected thermal engineer and a social theorist. Diesel’s inventions have three points in common: they relate to heat transfer by natural physical processes or laws; they involve markedly creative mechanical design; and they were initially motivated by the inventor’s concept of sociological needs. Rudolf Diesel originally conceived the diesel engine to enable independent craftsmen and artisans to compete with industry.

At Augsburg, on August 10, 1893, Rudolf Diesel’s prime model, a single 10-foot (3.0 m) iron cylinder with a flywheel at its base, ran on its own power for the first time. Diesel spent two more years making improvements and in 1896 demonstrated another model with a theoretical efficiency of 75%, in contrast to the 10% efficiency of the steam engine. By 1898, Diesel had become a millionaire. His engines were used to power pipelines, electric and water plants, automobiles and trucks, and marine craft. They were soon to be used in mines, oil fields, factories, and transoceanic shipping.

How diesel engines work

Early fuel injection systems

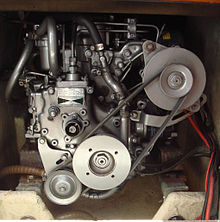

Diesel’s original engine injected fuel with the assistance of compressed air, which atomized the fuel and forced it into the engine through a nozzle (a similar principle to an aerosol spray). The nozzle opening was closed by a pin valve lifted by the camshaft to initiate the fuel injection before top dead centre (TDC). This is called an air-blast injection. Driving the three stage compressor used some power but the efficiency and net power output was more than any other combustion engine at that time.

D

Figure 3. A Diesel engine built by MAN AG in 1906

iesel engines in service today raise the fuel to extreme pressures by mechanical pumps and deliver it to the combustion chamber by pressure-activated injectors without compressed air. With direct injected diesels, injectors spray fuel through 4 to 12 small orifices in its nozzle. The early air injection diesels always had a superior combustion without the sharp increase in pressure during combustion. Research is now being performed and patents are being taken out to again use some form of air injection to reduce the nitrogen oxides and pollution, reverting to Diesel’s original implementation with its superior combustion and possibly quieter operation. In all major aspects, the modern diesel engine holds true to Rudolf Diesel’s original design, that of igniting fuel by compression at an extremely high pressure within the cylinder. With much higher pressures and high technology injectors, present-day diesel engines use the so-called solid injection system applied by Herbert Akroyd Stuart for his hot bulb engine. The indirect injection engine could be considered the latest development of these low speed hot bulb ignition engines.

Mechanical and electronic injection

M

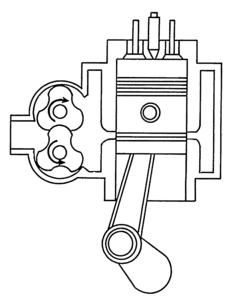

Figure 4. Diesel engine model, left side

any configurations of fuel injection have been used over the past century (1901–2000). Most present day (2008) diesel engines use a mechanical single plunger high-pressure fuel pump driven by the engine crankshaft. For each engine cylinder, the corresponding plunger in the fuel pump measures out the correct amount of fuel and determines the timing of each injection. These engines use injectors that are very precise spring-loaded valves that open and close at a specific fuel pressure. Separate high-pressure fuel lines connect the fuel pump with each cylinder. Fuel volume for each single combustion is controlled by a slanted groove in the plunger which rotates only a few degrees releasing the pressure and is controlled by a mechanical governor, consisting of weights rotating at engine speed constrained by springs and a lever. The injectors are held open by the fuel pressure. On high-speed engines the plunger pumps are together in one unit. The length of fuel lines from the pump to each injector is normally the same for each cylinder in order to obtain the same pressure delay.

Direct injection

D

Figure 5. Diesel engine model, right side

irect injection diesel engines have injectors mounted at the top of the combustion chamber. The injectors are activated using one of two methods – hydraulic pressure from the fuel pump, or an electronic signal from an engine controller.

Types Size Groups.

T

Figure 6. A Yanmar 2GM20 marine diesel engine, installed in a sailboat

here are three size groups of Diesel engines:

Small – Under 188 kW (252 hp) output

Medium

Large

Basic Types of Diesel Engines

There are two basic types of Diesel Engines:

Four Cycle

Two Cycle

Figure 7. Two Cycle Diesel engine with Roots blower, typical of Detroit Diesel and someElectro-Motive Diesel Engines

Gas generator

Before 1950, Sulzer started experimenting with two-stroke engines with boost pressures as high as 6 atmospheres, in which all the output power was taken from an exhaust gas turbine. The two-stroke pistons directly drove air compressor pistons to make a positive displacement gas generator. Opposed pistons were connected by linkages instead of crankshafts. Several of these units could be connected to provide power gas to one large output turbine. The overall thermal efficiency was roughly twice that of a simple gas turbine. This system was derived from Raúl Pateras Pescara’s work on free-piston engines in the 1930s.

Figure 8. Arrow indicates opening from pre-chamber

Modern High- and Medium-speed Engines

As with petrol engines, there are two classes of diesel engines in current use: two-stroke and four-stroke. The four-stroke type is the “classic” version, tracing its lineage back to Rudolf Diesel’s prototype. It is also the most commonly used form, being the preferred power source for many motor vehicles, especially buses and trucks. Much larger engines, such as used for railroad locomotion and marine propulsion, are often two-stroke units, offering a more favourable power-to-weight ratio, as well as better fuel economy. The most powerful engines in the world are two-stroke diesels of mammoth dimensions.

Two-stroke diesel engine operation is similar to that of petrol counterparts, except that fuel is not mixed with air before induction, and the crankcase does not take an active role in the cycle. The traditional two-stroke design relies upon a mechanically driven positive displacement blower to charge the cylinders with air before compression and ignition. The charging process also assists in expelling (scavenging) combustion gases remaining from the previous power stroke.

Advantages and disadvantages versus spark-ignition engines

Power and fuel economy

D

Figure 9. The MAN B&W 5S50MC 5-cylinder, 2-stroke, low-speed marine diesel engine. This particular engine is found aboard a 29,000 tonne chemical carrier.

iesel engines usually have longer stroke lengths chiefly to facilitate achieving the necessary compression ratios, but also to reduce the optimal operating speed (rpm). As a result piston and connecting rods are heavier and more force must be transmitted through the connecting rods and crankshaft to change the momentum of the piston. This is another reason that a diesel engine must be stronger for the same power output as a petrol engine. The average diesel engine has a poorer power-to-weight ratio than the petrol engine. This is because the diesel must operate at lower engine speeds and because it needs heavier, stronger parts to resist the operating pressure caused by the high compression ratio of the engine and the large amounts of torque generated to the crankshaft. In addition, diesels are often built with stronger parts to give them longer lives and better reliability, important considerations in industrial applications.

Emissions

In diesel engines, conditions in the engine differ from the spark-ignition engine, since power is directly controlled by the fuel supply, rather than by controlling the air supply. Thus when the engine runs at low power, there is enough oxygen present to burn the fuel, and diesel engines only make significant amounts of carbon monoxide when running under a load. Diesel exhaust is well known for its characteristic smell; but this smell in recent years has become much less because the sulfur is now removed from the fuel in the oil refinery. Diesel exhaust has been found to contain a long list of toxic air contaminants. Among these pollutants, fine particle pollution is perhaps the most important as a cause of diesel’s harmful health effects.

Noise

The characteristic noise of a diesel engine is variably called diesel clatter, diesel nailing, or diesel knock. Diesel clatter is caused largely by the diesel combustion process; the sudden ignition of the diesel fuel when injected into the combustion chamber causes a pressure wave. Engine designers can reduce diesel clatter through: indirect injection; pilot or pre-injection; injection timing; injection rate; compression ratio; turbo boost; and exhaust gas recirculation (EGR). Common rail diesel injection systems permit multiple injection events as an aid to noise reduction. Diesel fuels with a higher cetane rating modify the combustion process and reduce diesel clatter. CN (Cetane number) can be raised by distilling higher quality crude oil, by catalyzing a higher quality product or by using a cetane improving additive.

A combination of improved mechanical technology such as multi-stage injectors which fire a short “pilot charge” of fuel into the cylinder to initiate combustion before delivering the main fuel charge, higher injection pressures that have improved the atomisation of fuel into smaller droplets, and electronic control (which can adjust the timing and length of the injection process to optimise it for all speeds and temperatures), have partially mitigated these problems in the latest generation of common-rail designs, while improving engine efficiency.

6. SAFETY

6.1. Fuel flammability

Diesel fuel has low flammability, leading to a low risk of fire caused by fuel in a vehicle equipped with a diesel engine.

In yachts diesels are used because petrol engines generate combustible vapors, which can accumulate in the bottom of the vessel, sometimes causing explosions. Therefore ventilation systems on petrol powered vessels are required.

The United States Army and NATO use only diesel engines and turbines because of fire hazard. Although neither gasoline nor diesel is explosive in liquid form, both can create an explosive air/vapor mix under the right conditions. However, diesel fuel is less prone due to its lower vapor pressure, which is an indication of evaporation rate. The Material Safety Data Shee for ultra-low sulfur diesel fuel indicates a vapor explosion hazard for diesel indoors, outdoors, or in sewers.

US Army gasoline-engined tanks during World War II were nicknamed Ronsons, because of their greater likelihood of catching fire when damaged by enemy fire. (Although tank fires were usually caused by detonation of the ammunition rather than fuel).

6.2. Maintenance hazards

Fuel injection introduces potential hazards in engine maintenance due to the high fuel pressures used. Residual pressure can remain in the fuel lines long after an injection-equipped engine has been shut down. This residual pressure must be relieved, and if it is done so by external bleed-off, the fuel must be safely contained. If a high-pressure diesel fuel injector is removed from its seat and operated in open air, there is a risk to the operator of injury by hypodermic jet-injection, even with only 100 psi pressure. The first known such injury occurred in 1937 during a diesel engine maintenance operation. CONCLUSION

In conclusion I could say, that Diesel is more than just trucks – it’s a driving force behind today’s technology. Think about all the vehicles and equipment running on diesel engines – oil rigs, power plants, hydraulic systems, locomotives, cargo ships, farming equipment, construction vehicles, mining equipment, and of course diesel trucks. After Diesel’s death, the Diesel engine underwent much development and became a very important replacement for the steam piston engine in many applications. Because the diesel engine required a heavier, more robust construction than a gasoline engine, it was not widely used in aviation.

Diesel engines have been around for more than a century, but only now are we realizing their true potential. The diesel engine is no longer viewed as nothing more than a loud and polluting nuisance. With modern technology, the diesel engine has transformed into an efficient power source that can still be used in a time where we, as humans, have become more aware of the negative impact our behaviors are having on the environment.

Looking to our future, our relationship with the oil industries and our dependency on foreign oil, hopefully, will drive us to explore alternatives with a more open mind. Experiments like the Veggie Van and Journey to Forever demonstrate what is possible if we are willing to change in a positive direction or maybe it is to revert back to the original vision of Rudolf Diesel and his engine.

Key Vocabulary

Plunger (is a type of positive displacement pump) – stūmoklis

Crankshafts (is the part of an engine that translates reciprocating linear piston motion into rotation) – alkūniniai velenai

Sulfur (is a chemical element with symbol S and atomic number 16) – siera

Combustion chamber (is the part of an engine in which fuel is burned.– degimo kamera

Nozzle ( is a device designed to control the direction or characteristics of a fluid flow) – purkštuvas

Ignition (the raising of a substance to its ignition point, as by electric current, friction, or mechanical shock) – uždegimas

Locomatives (a self-propelled vehicle, usually electric or diesel-powered, for pulling or pushing freight or passenger cars on railroad tracks) – lokomotyvai

Piston (a solid cylinder or disk that fits snugly into a larger cylinder and moves under fluid pressure) – vožtuvas

Liquid (matter or a specific body of matter in this state) – skystas

Pressure (the application of continuous force by one body on another that it is touching; compression) – spaudimas

Implementation (to put into practical effect; carry out) – vykdymas

Crude (being in an unrefined or natural state; raw) – neapdirbtas

Flammability (easily ignited and capable of burning rapidly; inflammable) – degumas

Evaporation (to convert or change into a vapor) – garinimas

Detonation (the act of exploding) – sprogimas, detonacija

Craftsmen (men who practice a craft with great skill) – meistras

Thermal (a rising current of warm air) – kylanti šilto oro srovė

Crankcase (the metal case enclosing the crankshaft and associated parts in a reciprocating engine) – karteris

Contaminants (one that contaminates; a contaminant) – teršalai

Carbon (a naturally abundant nonmetallic element that occurs in many inorganic and in all organic compounds) – anglis

Diesel (that Diesel is more than just trucks) – dyzelinis

Fuel (fuel when injected) – degalai

Injection (Direct injection diesel engines) – įpurkšti

Natural (to their natural environments) – natūralus

Hazards (potential hazards in engine) – pavojai

Available (energy available in the fuel) – pasiekimas

Understood (Diesel understood) – suprantama

Theoretical (thermodynamics and the theoretical) – teorinis

Mixture (letting the mixture expand) – mišinys

Patensts (filed patents and) – patentai

Pumps (mechanical pumps) – siurbliai

Pressure (by pressure-activated) – slėgis

Transfert (without transfer of heat) – pervežimas

Design (creative mechanical design) – dizainas

Development (latest development of these low) – plėtra

Cylinder (with in the cylinder) – cilindras

Combustion (combustion engine at) – degimas

Plunger (mechanical single plunger) – stūmuoklis

Mounted (injectors mounted) – sumontuotas

Hydraulic (hydraulic pressure) – hidraulinis

Signal (electronic signal) – signalas

Two-stroke (two-stroke engines) – dvitaktis

Turbine (gas turbine) – turbina

Similar (operation is similar) – panašus

Chiefly (lengths chiefly) – daugiausia

Necessary (necessary compression) – Būtinas

Force (more force must) – jėga

Power (power-to-weight) – jėga

Realiability (and better reliability) – patikimumas

Spark-ignition (spark-ignition engine)- kibirkštinis

Oxygen (is enough oxygen) – deguonis

Catalyzing (by catalyzing a higher) – katalizatorius

Generation (generation of common-rail) – kartos

Atomisation (improved the atomisation) – išpurškinas

Vessels (vessels are required)- Laivai

References

1. http://www.deere.com/en_US/docs/html/jdps_brochure/default.html#Tier-1

2. http://www.animatedengines.com/diesel.html

3. Anthony John Wharton (2003). Diesel engines. Burlington, Linacre House.

4. Nigel Calder (2007). Marine Diesel Engines. International Marine.

5. http://illumin.usc.edu/printer/185/diesel-engines-is-old-technology-actually-green-technology/

6. http://www.thefreedictionary.com/